3. Risky factors in the mechanical engineering

The movement of tools, machinery, and other working equipment is a major source of risk in mechanical engineering. The machine and the style of operation both affect how much damage is done.

In addition to machines, metal dust or chemicals used during processing can also be the cause of occupational diseases.

3.1 Risky factors evaluation.

When it comes to risky factors, listed as:

- Movement structure of machines, a lack of safety safeguards for moving machinery parts, high radiation areas, etc.

- Exposed wires, electrical leakage.

- Compressed air tanks are not set up appropriately.

- Sharp metal pieces.

- Machines are configured incorrectly or moved in the wrong directions by the workforce.

- Working area at heights is unsafe without safety coverings.

3.2 Common workplace accidents and injuries.

Accidents and injuries are danger to the labors:

- Electrical shock.

- Being cut to the body by machines or sharp metal pieces.

- Being rolled with clothes and hair to the machine.

- Crush injury of hands.

- Burrs of metals, materials can harm or pierce the human eye.

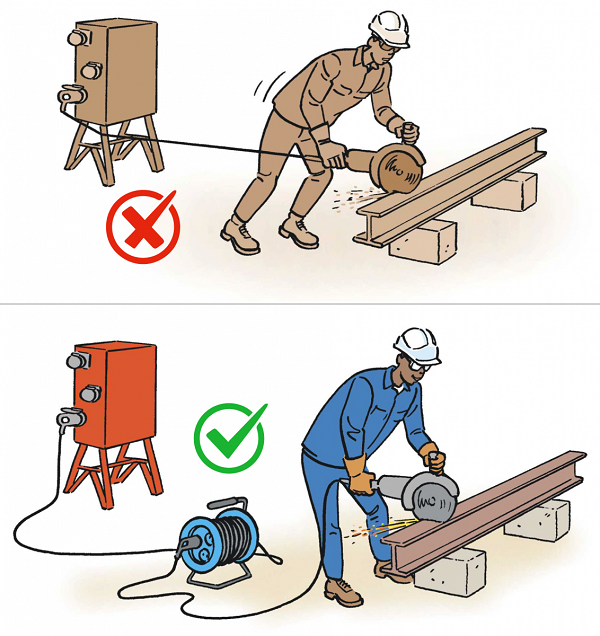

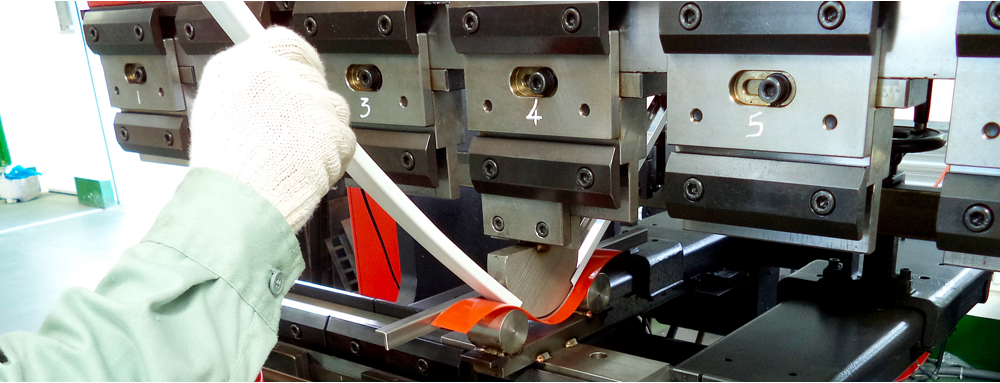

Image 3: Accidents during the use of machinery.

(Photo source: Basic educational resource on workplace safety and sanitation in Japan)

4. The measures of accident prevention

- Periodical inspections of machinery and electrical equipment.

- Adequate lighting conditions, positive working environment.

- 5S implementation in the workplace.

- After assessing a high-risk area, precautions are made to prevent and minimize accidents or injuries.

- Organization for occupational safety training.

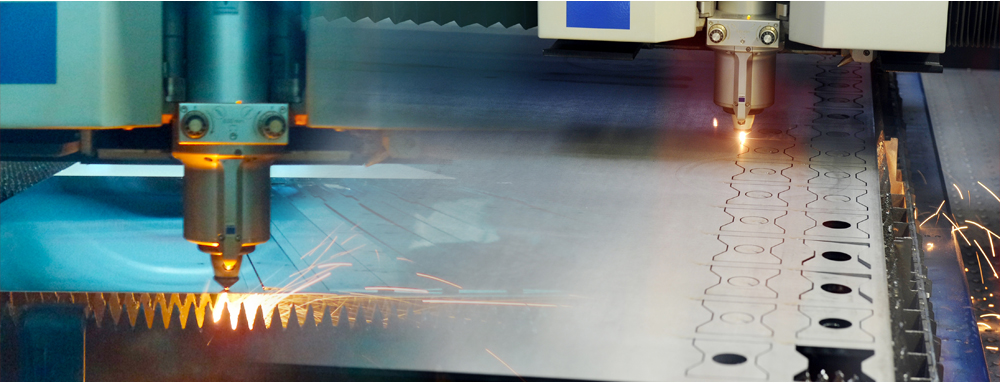

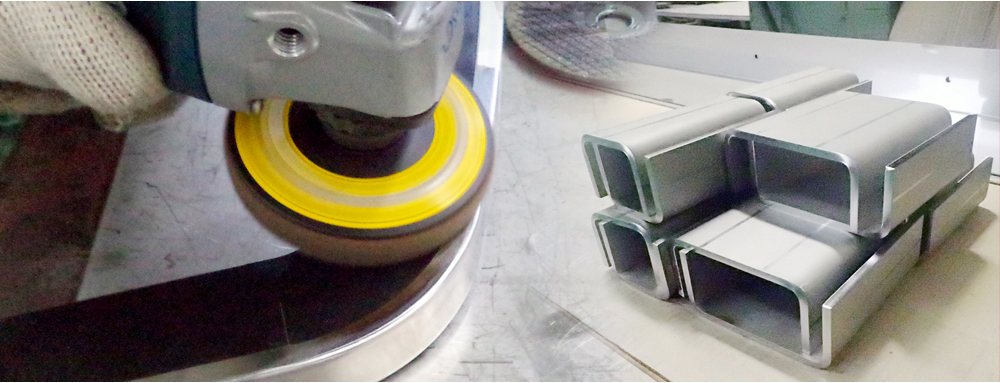

Image 4: Safety implementation.

(Photo source: Southern safety)

- Dangerous areas must have warning signs.

- Plugs, switches must be disconnected when not in use.

- Protective equipment, machinery coverings must be equipped to minimize the possibility of interaction between the labors and dangerous parts of the machine such as gears, cutting blades, rollers, etc.

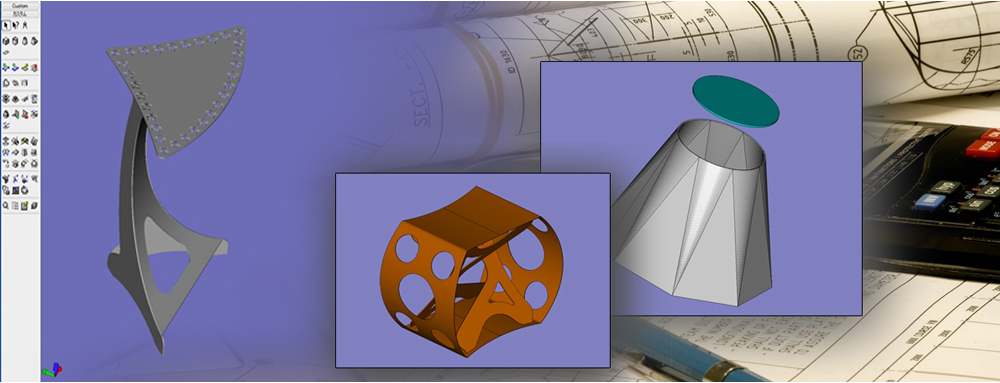

Some of products are used to safeguard machinery manufactured by ISHO VIETNAM:

Product #1: GEAR COVER

Purpose: To protect the labors from colliding with gears while the machine is running.

Image 5: Gear cover (1)

Image 6: Gear cover (2)

When required, we always offer practical recommendations to assist our customers in developing goods that are most suitable.

Product #2: ROLLER COVER

Purpose: To cover the working scope of rollers, minimize the possibility of being rolled with hands, hair to the rollers.

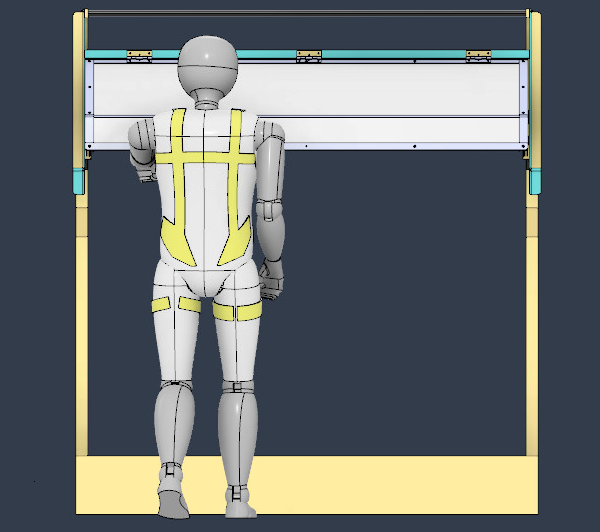

Image 7: 3D simulation.

Image 7: 3D simulation.

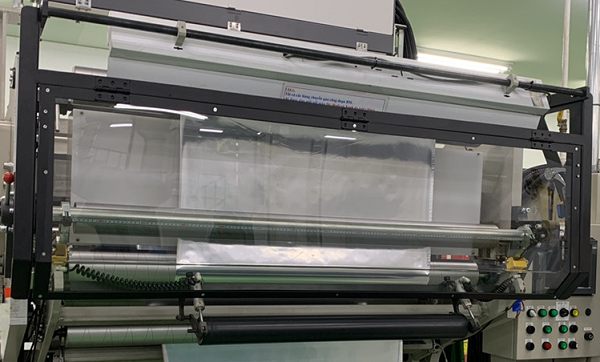

Image 8: On-site installation.

Hazards in the workplace, both subjective and objective, cannot be avoided. For the safest environment, take safeguards if at all possible.

Online:

Online:  Total:

Total: