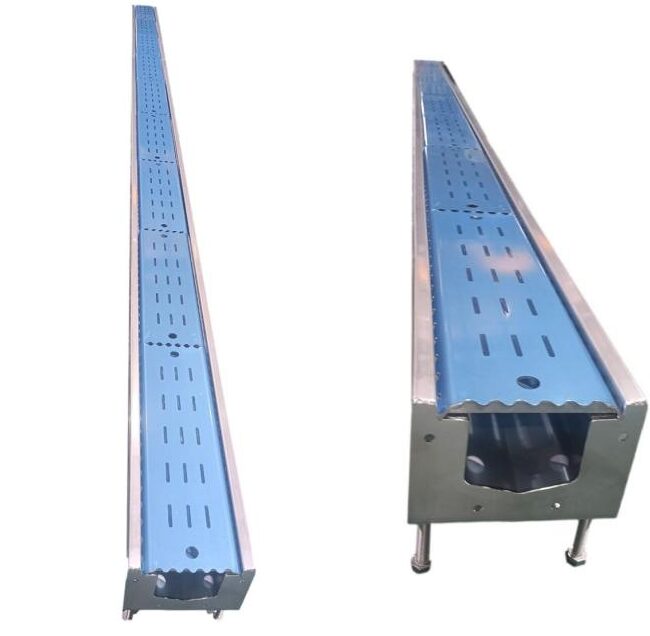

One-stop service for laser cutting, bending, and welding.

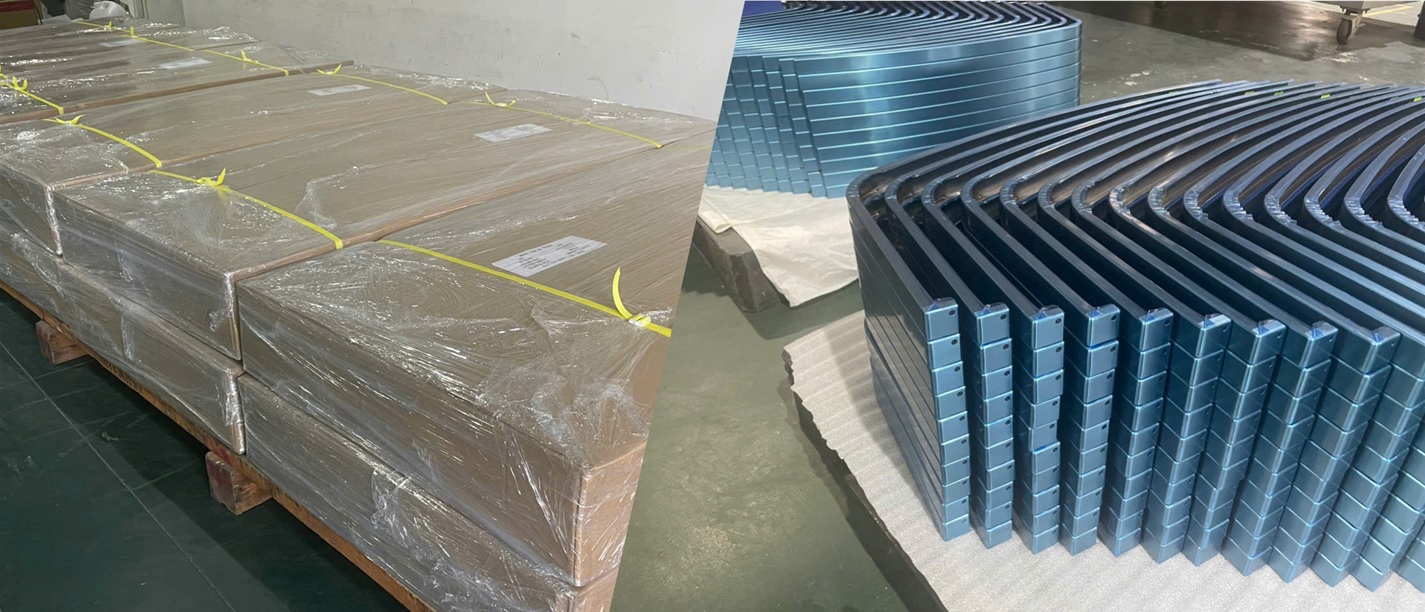

From single-piece prototypes to mass production, we ensure high reproducibility and consistency.

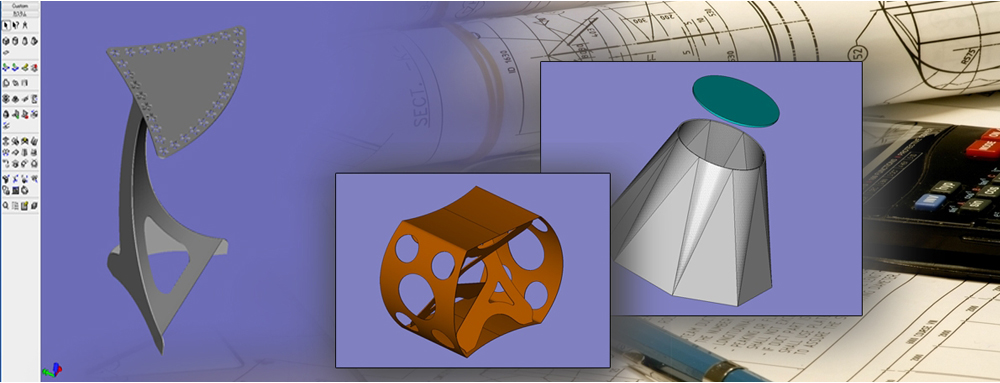

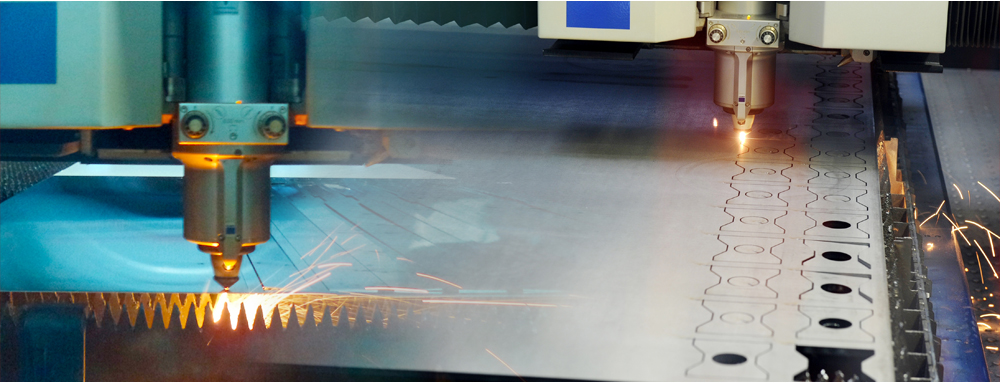

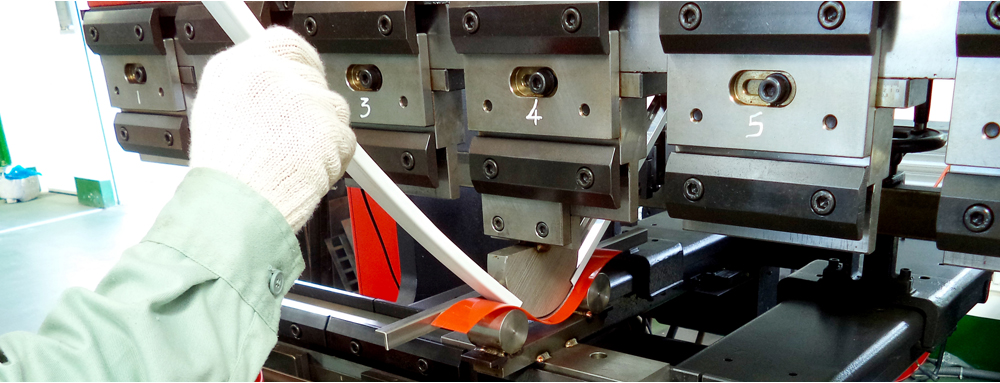

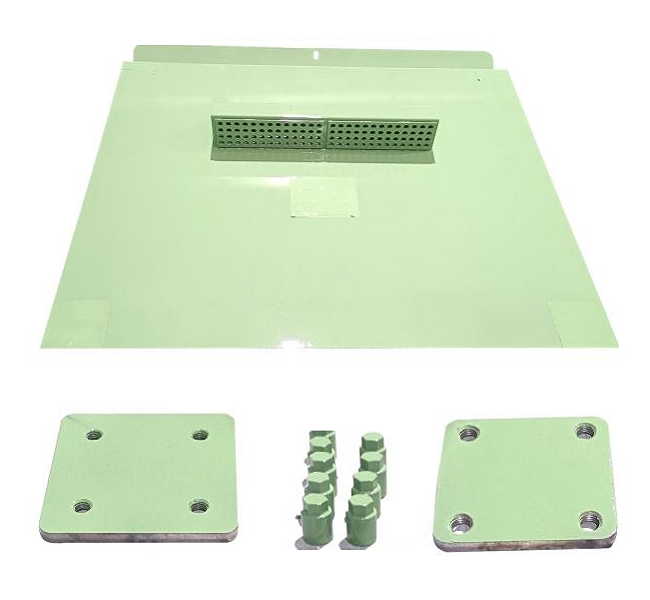

We clearly introduce the range of available processing methods such as laser cutting, bending, and welding.

Isho Vietnam provides sheet metal processing services in Vietnam, built upon over 60 years of technical expertise and quality standards developed by our headquarters in Japan.

We have been receiving an increasing number of new orders from companies that faced challenges such as “other suppliers couldn’t handle the request” or “communication took too long.” This growth stands as proof of the trust and confidence our customers place in us.

Business hours: 9:00 AM – 6:00 PM

We are open all year round

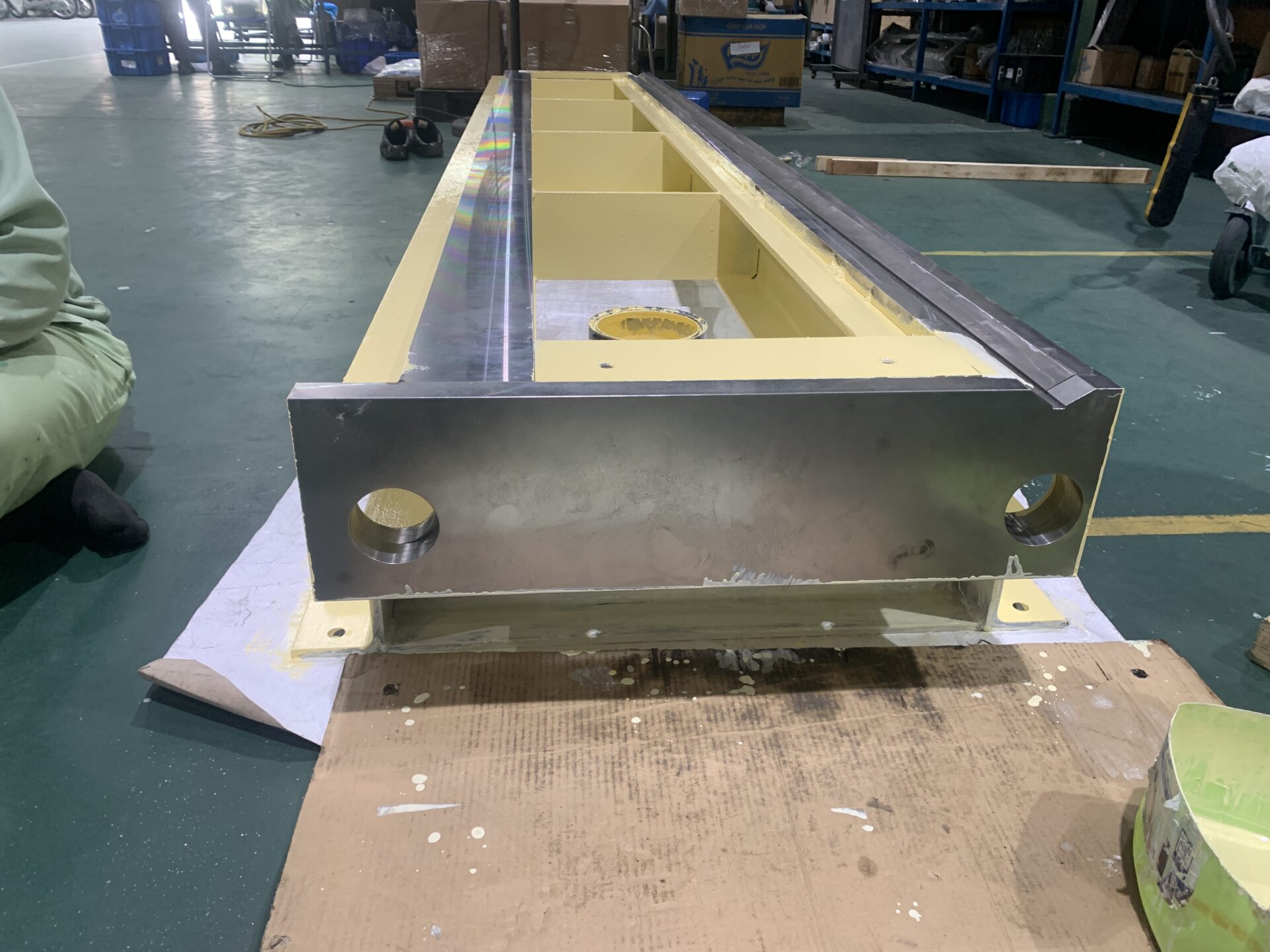

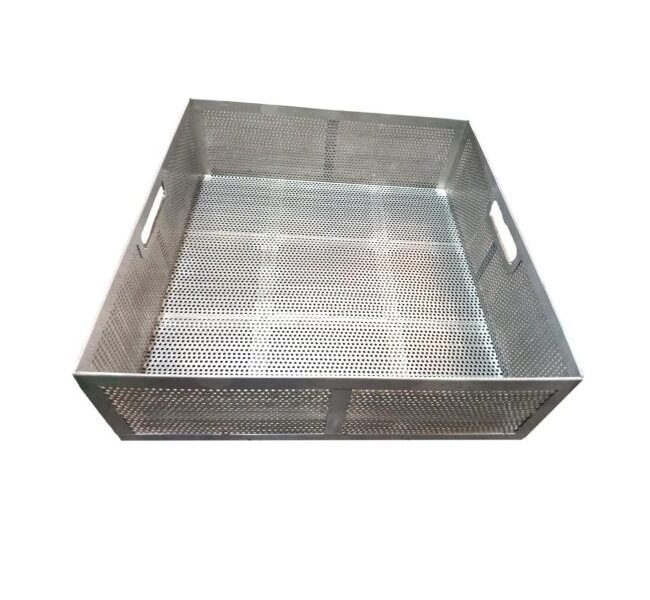

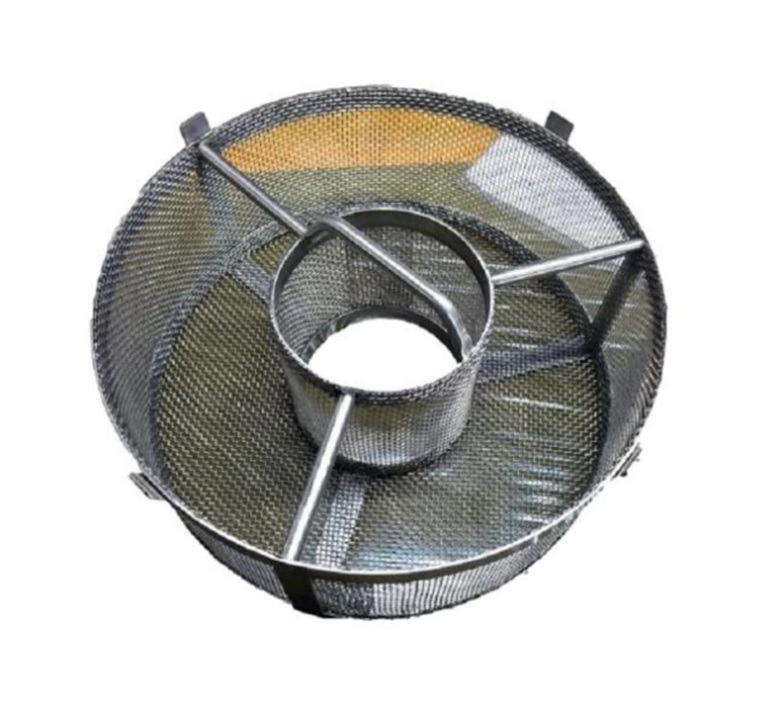

We own a wide range of equipment in-house, including German-made TRUMPF laser processing machines, shearing machines, seam welders, three-roll bending machines, band saws, and spot welders.

Our system enables consistent support from small-lot prototyping to mass production and assembly.

Discover the facilities and achievements that support Isho Vietnam’s manufacturing excellence.

Yes, we can handle small-lot prototypes starting from just one or two pieces. Please feel free to consult us for design verification or prototype evaluation.

Yes, we work with various materials such as aluminum, steel, stainless steel, and titanium. Please specify your desired material and thickness in your drawing.

Yes, since Japanese-speaking staff are always on site, orders with Japanese drawings and specifications can be processed smoothly.

Of course. We can handle prototype or small-lot orders even for first-time clients, and our Japanese-speaking staff will assist you with drawing and specification confirmation.

We have a system in place to ensure a smooth and worry-free first transaction.

Absolutely. We will review your drawings or actual samples, analyze the issues, and provide full support from improvement proposals to re-manufacturing.

In the unlikely event of a defect, we promptly identify the cause and take corrective action such as re-manufacturing or re-inspection.

We are committed to providing sincere and speedy follow-up, including preventive measures to avoid recurrence.